|

Home Page

Introduction

Aluminium

Extrusion

Roller Covers

Flight

Bar Pads

Walking

Beam Pad

Cooling

Table Pad

Endless

Belts

Glass

Industry

Conveyor

Belts

New

Combo Belts

Tapes

and Ropes

Seamless

Tubing

Fabricated

Pads

Other

Markets

Specifications

Product

Properties

Treatments

No

Charge Sample

|

– HEAT RESISTANT TEXTILES &

BELTING –

CONVEYOR BELTING

|

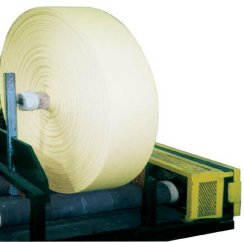

CONVEYOR BELTING

TUFF TEMP has designed and developed a family of unique high temperature resistant belting products that are ideal for use as conveyor belting within the hot end of primary

glass plants and aluminum extrusion plants For conveyance

applications in severe manufacturing processes such as hot glass and / or hot aluminum, conveyor belting must exhibit superior temperature resistance, superior cut and abrasion resistance, and superior mechanical performance. Conveyor belting must also be totally non-marking and be safe for the finish quality of the customer's product. |

|

|

We understand that our customers are typically running their

manufacturing plants 24 hours a day, 7 days a week, 365 days a year. Any downtime that the customer experiences in manufacturing is unrecapturable, permanently lost revenue. With that mindset, our focus is to supply the longest lasting, most durable conveyor belts in the world, so that our customers can achieve the longest continuous production runs, with minimal costly maintenance down-time.

|

|

Our line of conveyor belting products has been uniquely engineered to meet all of these criteria, and it is our mission to provide our customers with the

absolute longest belting wear life .

|

|

HIGH-DENSITY, MULTI-LAYERED CONSTRUCTIONS:

Superior engineered conveyor belting starts with utilizing specialty high temperature resistant yarns.

We utilize mechanically enhanced 100% para-aramid synthetic fiber

yarns, and other high temperature resistant specialty fibers such as PBI, PBO and Stainless Steel. Next, we construct our conveyor belting utilizing high-density, multi-layered weaving, to create thick, tough, and ultra-durable woven belts up to 24" wide (610 mm) and 3/8" thick (9 mm). Next, we apply in-house, one of our value-added

finishing treatments to the belting to enhance the end use durability and further strengthen the mechanical performance.

The end result of these manufacturing efforts is that we have pushed

our conveyor belts well beyond the normal temperature ratings of the base fibers. |

|

- For intermittent contact applications such as conveyance

of hot glass and hot aluminum extrusions, TUFF TEMP conveyor

belting has proven temperature resistance up to 1,400º F /

760º C.

Our conveyor belting is typically used within the hot end

of glass Pressware and Hollowware plants to convey hot ware from

the press molds in the Forming section, up to the entrance of the

annealing lehr. Ware contact temperatures on our belting can

typically exceed 1,300º F / 690º C our conveyor belting is

used in the hot end by many of the leading TV Glass manufacturers,

and Tableware and Ovenware manufacturers, where glass contact

temperatures are amongst the hottest in the industry. |

- Our conveyor belts exhibit superior mechanical performance, including minimal belt stretch, and stable tracking within the center of the conveyor bed.

Our pre-stretches all conveyor belts under high tension in our value-added

Water Stretched finishing process. The end result is that we significantly reduce and / or eliminate potential belt stretch following installation.

- Our conveyor belts will

NOT check, scratch or mark even the most sensitive surface finishes of hot glass ware or hot aluminum extrusion profiles.

Our conveyor belting is

an ideal replacement for traditional chain and / or metal

belts, which typically require costly high energy burners to help prevent checks and marks. No burners are required when running

our belts,

significantly reducing your energy costs, while improving the surface quality of your ware.

- Our conveyor belts can be supplied pre-cut and pre-laced for your exact conveyor lengths, ensuring no waste and minimal set-up time for your plant personnel.

We pre-lace conveyor belts with an appropriate size stainless clipper lacing, and then reinforces the strength of the lacing by applying our value-added Wear Gard treatment to the join. The Wear Gard hardens around the lacing with minimal dry time, and ensures optimal strength, so that the lacing will not pull or tear out.

|

|

Our conveyor belting is supplied in a wide range of widths, thicknesses, and plies, to cover a

multitude of hot end applications. Such depth of selection in our

product lines ensures that the customer receives the most cost-effective belting product for their particular

conveyance application. |

|

| Our conveyor belting is specifically available up to a maximum width of 24" (610 mm), and a maximum thickness of 3/8" (9 mm) (nominal).

We have also recently developed a new breakthrough high

temperature resistant conveyor belting that has been designed for the hottest, heaviest, and most severe hot end conveyance applications. Known as our

"Combo and Blended Belting", due to their blended construction of multiple specialty high temperature resistant fibers, they have quickly proved to be the longest lasting and most durable high temperature belts available today. |

|

With over 25 years of industry experience

devoted to high temperature resistant conveyor belting,

we are firmly committed to R&D, and to the pursuit of product innovation.

Please feel free to contact

us to discuss your particular hot end application. It is our pleasure to

provide you with samples of our belting to test in your plant so that we can prove our value, and help you improve the

productivity of your manufacturing process. |

|

|