A

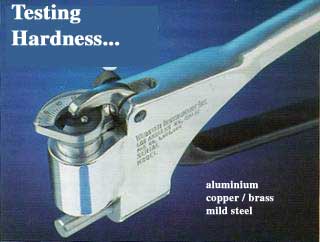

Portable, Fast, Accurate Hardness Gauge Available in Several Models for Testing

Materials such as

A

Portable, Fast, Accurate Hardness Gauge Available in Several Models for Testing

Materials such as

A

Portable, Fast, Accurate Hardness Gauge Available in Several Models for Testing

Materials such as

A

Portable, Fast, Accurate Hardness Gauge Available in Several Models for Testing

Materials such as

Aluminium,

Brass,

Copper,

Mild Steel.

Quickly identify tempers.

Tests a variety of shapes that other testers cannot check: Extrusions, Tubing and Flat Stock.

Uses and Applications:

· For identifying heat-treated from non-heat-treated parts

· Provides correlation between a bench mounted hardness tester and the production line

· For segregating materials in stock

· For differentiating between soft or work-hardened material

· For identifying parts made from improper or substandard alloys

· Checking for proper heat-treatment response

· Useful in conjunction with stationary laboratory hardness testers. Gives a rapid 100% check on parts which would consume many man-hours with slower operating test equipment

· can be used on assemblies which cannot be brought to the laboratory

|

|

|

Each

tester is shipped in a fitted case with a spare penetrator, adjusting

wrench and standard test strip |

Features:

· One hand operation and portability

·

Round 9,5 mm diameter anvil permits testing a great variety

of shapes Simple operation permits readings independent of the operator's skill

· Test is made by simply applying pressure to the handles until "bottom" is felt

· Easy-to-read dial indicator with 20 graduations permits use of the tester as "go" and "no-go" gauge, or values can be converted to other standard scales

· Standard hardness gauge tests materials up to 1/4 inch in thickness

·

Increased

capacities available up to 25,4 mm

Operation:

This

sectional view shows the basic design principle of the Webster Hardness Tester.

The different models vary only in penetrator and load spring design. These

combinations give the ability to test a wide range of hardnesses and metals.

This

sectional view shows the basic design principle of the Webster Hardness Tester.

The different models vary only in penetrator and load spring design. These

combinations give the ability to test a wide range of hardnesses and metals.

The penetrator housing, which contains the penetrator and load spring, slides vertically in the frame of the tester when pressure is applied to the handles. Only sufficient pressure is needed to "bottom" the lower face of the housing against the work. Resistance of the work to the penetrator causes the penetrator to recede into the housing against the spring pressure. The degree of penetration on the test specimen is indicated on the dial indicator sitting on top of the housing assembly. The load can be varied by adjusting the nut above the load spring, permitting the dial reading to be easily corrected against a test block of known hardness.

A penetration of 0.010 inch produces a full scale reading on the dial indicator. Therefore materials in the softer hardness range should be of sufficient thickness so that the anvil will not influence the test and produce an "anvil effect". In general, soft materials under 0,60 - 0.75 mm thickness will not give true readings.

Different models:

Webster hardness testers are available in the following three models:

Model B for Aluminium and Aluminium Alloys

Model B-75 for Brass and Mild Steel

Model BB-75 for Copper

|

|

|

for inquiries : Nokta

Metal Ltd

Ismailpasa Sokak No: 50 Kosuyolu, Kadikoy, 34718 Istanbul, Turkiye

Tel : +90 (216) 545 7550 /

Fax: +90 (216) 545 7549

e-mail